Key Processes of Battery Recycling

-

01

Black MassFeedstock

-

02

Thermochemical Treatment

-

03

Leaching And Filtration

-

04

Crystallization

-

04

Crystallization

-

05

Drying

-

06

Lithium Hydroxide or Lithium Carbonate Product

Conventional

Process

65-75% Lithium Recovery

Complex Process

High Sludge Production

Yielding of Low-Value Products

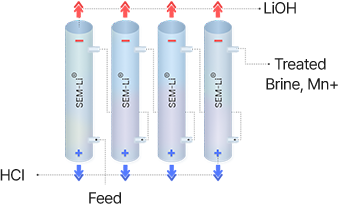

SEM

Process

85-95% Lithium Recovery

Simple Process

Minimal Sludge Discharge

Production of High-Value Core Materials

Brine Pool And Wastewater

Lithium Production From Brine & Wastewater

Harvesting Lithium From Brine Pool

-

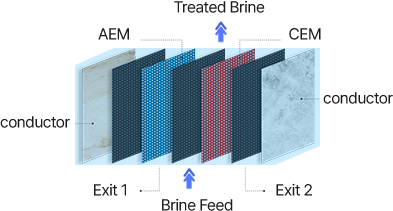

RAW LITHIUM BRINElithium in the brine Treated Brine (Lithium-free) LITHIUM CONCENTRATE1Lithium ions are absorbed selectively to solid Materials highly selective for lithium (acts like a chemical filter). 2Brine without lithium leaves the system for injection back into the reservoir. 3Stripping fluid removes the lithium ions to produce a high grade, high purity concentrate.

Lithium Recovery from Lithium-Laden Wastewater

-

Proprietary sorbent highly selective for Lithium RAW LITHIUM BRINE Treated Brine (Lithium-free) to be Re-injected LITHIUM CONCENTRATE TO BE REFINED

- Lithium Production from Low-Grade Salt Lakes and Lithium-Containing Wastewater

- Low Transmembrane Differential Pressure

- Daily Lithium Production

- Land Degradation and Environmental Pollution Issues

- Eliminates the Need for Salt Farms as Lithium Enrichment Sites (reduces investment cost)

Conventional Process

Lithium Concentration/Precipitation/Purification Technology

18 to 24 Months

30 – 50

6000 ton

Low

0.5 – 2 Mt

Limited Brine Pool Area

Comparison

Parameters

Operation Time

Recovery (%)

Brine Pool Consumption

Performance

Water Loss

Production Sustainability

SEM DLE Process

SEM DLET Proprietary Technology

Less than 24 hrs

90 – 95

< 100 ton

High

Low

Scalable